The History Of Tunnel Pasteurization Revealed

Content create by-Klitgaard Davis

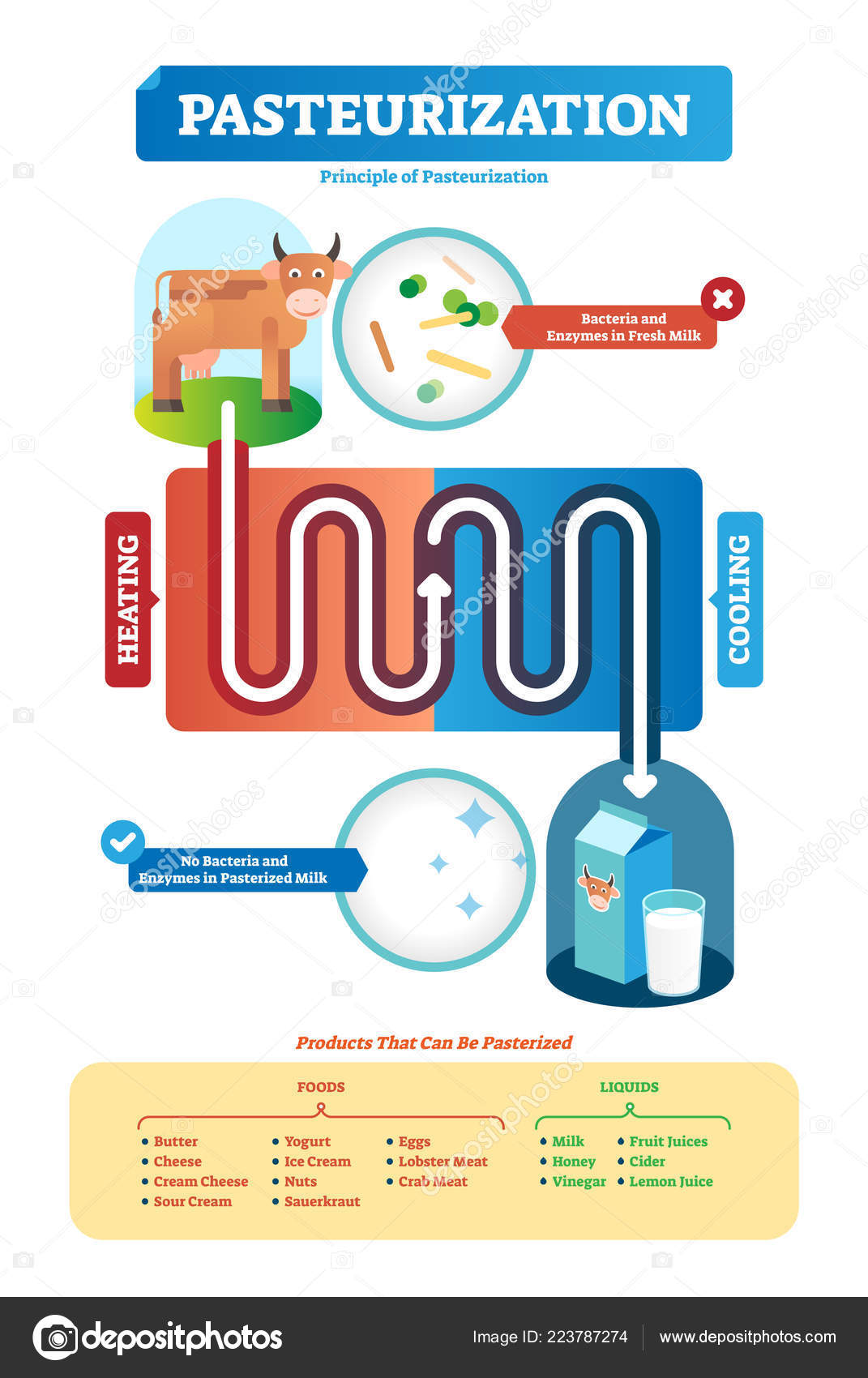

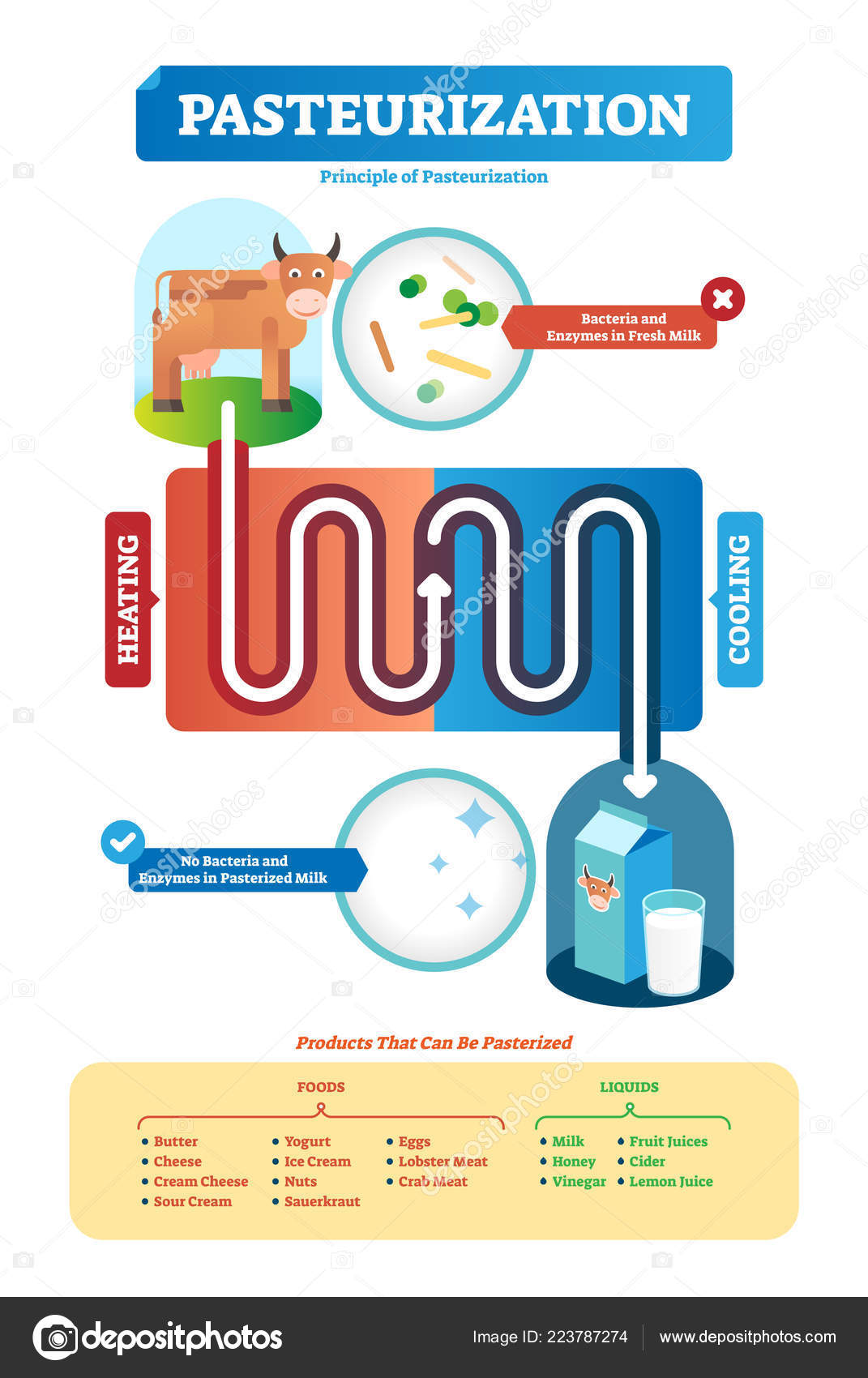

Packaged drink products can be gotten ready for enhanced conservation as well as service life; this is typically referred to as Tunnel pasteurization (2 ). It occurs by quickly heating and then cooling the already loaded item plans according to an automated thermal cycle. In the present write-up, we go over some essential realities concerning this prominent pasteurization technique.

This pasteurization is commonly employed in the manufacturing of premium, top notch, fresh as well as chilly beers and in the manufacturing of sparkling wine. However, in the past a number of years, this procedure has additionally been successfully used to prepare mostly all sorts of beverages, that include juices as well as distilled beverages. Additionally, this pasteurization process has actually additionally been effectively related to various other foodstuff consisting of cheese as well as ice cream. The concept behind this type of pasteurization is the heat transfer of alcohol, which then becomes water vapor. The objective of the beer pasteurization of liquors is to maintain the 'flavonoid' acid element of the beverage by preventing warm damages.

During the beer pasteurization of liquors, among the major benefits is that this technique shields the freshness of the beverage. This is due to the fact that throughout this procedure, warm does not move to the product. In the case of beer, this consists of stopping the formation of foam throughout air conditioning, which normally triggers foam development when cold beer is cooled. Furthermore, this technique aids to keep the taste and also preference of the beverage undamaged. On top of that, it avoids the browning or peeling of different products, which typically takes place throughout the cooling process, such as beer containers and also bottles.

As pointed out above, among the main advantages of this type of developing approach is that it supplies full defense to the beverage from warm transfer. Because of the fact that co2 is utilized to create the warmth in the first place, it is generally the outer layer of the beer which is warmth moved to the food, causing it ruining quickly. With this protection, beer brewers have had the ability to brew stronger, higher quality beer with reduced costs. Highly recommended Online site of such excellent quality beers include German pilsners, English ales and also British pale ales.

As a result of the special buildings of this process, some breweries are using the Tunnel pasteurization process to produce a limited quantity of beer for unique celebrations and also as presents. Tunnel pasteurization can preserve approximately 95% of the original flavor as well as color of a drink. There have actually been a number of efforts to duplicate this procedure with various means, yet to day none has been successful. The reason why no container is ever before totally eaten by the public results from the truth that the pasteurization process ruins the taste of the drink. As https://www.foodsafetynews.com/2016/02/six-kids-sickened-in-outbreak-linked-to-organic-pastures-raw-milk/ of fact, some professionals believe that it should be prohibited to market any kind of bottled beer under these conditions, as no person is legitimately permitted to ingest any type of non-pasteurized drink, also when it is refrigerated.

The process of pasteurization can additionally be applied to beer made in the house without the aid of a pasteurizer. It is usually made use of for set production and small-scale developing. Tunnel pasteurizers are not effective at maintaining greater alcohol web content beers, such as p.u (proprietary) beers, as a result of the reality that a high temperature of pasteurizing the wort before developing triggers the healthy proteins in the wort to denature, which in turn prevent healthy protein synthesis. Although a lot of house brewers use Tunnel pasteurization to preserve ales, they are not aware of its downsides therefore continue to boil the wort with all the beers to make certain that all the unwanted proteins are prepared away.

Nevertheless, lots of commercial manufacturers of packaged beer currently use Tunnel pasteurization to accomplish the exact same high criteria of preservation that bottled beer business have. This procedure includes applying pure carbon dioxide to the wort before its conversion to the fermenting phase. Pure co2 is extremely unwanted, as it inhibits the oxidation of the bacteria that live within the wort, stopping them from creating the wanted taste of the beer. When using a tunnel pasteurizer to accomplish this consistency, brewers can regulate precisely just how the beer is preserved during the brewing process.

In the past few years, Tunnel pasteurization has ended up being a preferred approach of preserving beers because of the huge range commercial manufacturing of packaged beers in the USA. Due to the high price of industrial grade components, it has been required to substitute home-brew components for those marketed in the commercial developing market. With the boost sought after for tunnels, however, house brewers have begun discovering alternative approaches of maintaining their very own beer. There are even some devoted teams of enthusiasts that advertise the technique of Tunnel pasteurization and also the use of tunnels for house brewers throughout the world. Tunneling is an effective ways of preservation when utilized in the correct manner.

Packaged drink products can be gotten ready for enhanced conservation as well as service life; this is typically referred to as Tunnel pasteurization (2 ). It occurs by quickly heating and then cooling the already loaded item plans according to an automated thermal cycle. In the present write-up, we go over some essential realities concerning this prominent pasteurization technique.

This pasteurization is commonly employed in the manufacturing of premium, top notch, fresh as well as chilly beers and in the manufacturing of sparkling wine. However, in the past a number of years, this procedure has additionally been successfully used to prepare mostly all sorts of beverages, that include juices as well as distilled beverages. Additionally, this pasteurization process has actually additionally been effectively related to various other foodstuff consisting of cheese as well as ice cream. The concept behind this type of pasteurization is the heat transfer of alcohol, which then becomes water vapor. The objective of the beer pasteurization of liquors is to maintain the 'flavonoid' acid element of the beverage by preventing warm damages.

During the beer pasteurization of liquors, among the major benefits is that this technique shields the freshness of the beverage. This is due to the fact that throughout this procedure, warm does not move to the product. In the case of beer, this consists of stopping the formation of foam throughout air conditioning, which normally triggers foam development when cold beer is cooled. Furthermore, this technique aids to keep the taste and also preference of the beverage undamaged. On top of that, it avoids the browning or peeling of different products, which typically takes place throughout the cooling process, such as beer containers and also bottles.

As pointed out above, among the main advantages of this type of developing approach is that it supplies full defense to the beverage from warm transfer. Because of the fact that co2 is utilized to create the warmth in the first place, it is generally the outer layer of the beer which is warmth moved to the food, causing it ruining quickly. With this protection, beer brewers have had the ability to brew stronger, higher quality beer with reduced costs. Highly recommended Online site of such excellent quality beers include German pilsners, English ales and also British pale ales.

As a result of the special buildings of this process, some breweries are using the Tunnel pasteurization process to produce a limited quantity of beer for unique celebrations and also as presents. Tunnel pasteurization can preserve approximately 95% of the original flavor as well as color of a drink. There have actually been a number of efforts to duplicate this procedure with various means, yet to day none has been successful. The reason why no container is ever before totally eaten by the public results from the truth that the pasteurization process ruins the taste of the drink. As https://www.foodsafetynews.com/2016/02/six-kids-sickened-in-outbreak-linked-to-organic-pastures-raw-milk/ of fact, some professionals believe that it should be prohibited to market any kind of bottled beer under these conditions, as no person is legitimately permitted to ingest any type of non-pasteurized drink, also when it is refrigerated.

The process of pasteurization can additionally be applied to beer made in the house without the aid of a pasteurizer. It is usually made use of for set production and small-scale developing. Tunnel pasteurizers are not effective at maintaining greater alcohol web content beers, such as p.u (proprietary) beers, as a result of the reality that a high temperature of pasteurizing the wort before developing triggers the healthy proteins in the wort to denature, which in turn prevent healthy protein synthesis. Although a lot of house brewers use Tunnel pasteurization to preserve ales, they are not aware of its downsides therefore continue to boil the wort with all the beers to make certain that all the unwanted proteins are prepared away.

Nevertheless, lots of commercial manufacturers of packaged beer currently use Tunnel pasteurization to accomplish the exact same high criteria of preservation that bottled beer business have. This procedure includes applying pure carbon dioxide to the wort before its conversion to the fermenting phase. Pure co2 is extremely unwanted, as it inhibits the oxidation of the bacteria that live within the wort, stopping them from creating the wanted taste of the beer. When using a tunnel pasteurizer to accomplish this consistency, brewers can regulate precisely just how the beer is preserved during the brewing process.

In the past few years, Tunnel pasteurization has ended up being a preferred approach of preserving beers because of the huge range commercial manufacturing of packaged beers in the USA. Due to the high price of industrial grade components, it has been required to substitute home-brew components for those marketed in the commercial developing market. With the boost sought after for tunnels, however, house brewers have begun discovering alternative approaches of maintaining their very own beer. There are even some devoted teams of enthusiasts that advertise the technique of Tunnel pasteurization and also the use of tunnels for house brewers throughout the world. Tunneling is an effective ways of preservation when utilized in the correct manner.

Created at 2021-10-22 21:46

Back to posts

This post has no comments - be the first one!

UNDER MAINTENANCE